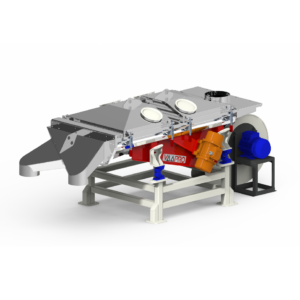

RECTANGULAR SCREENERS RVS-L

These sieves are highly versatile and can be fitted with multi-layer screens to meet various separation needs. The vibration motors are positioned on both sides of the screen, ensuring consistent and uniform motion. This setup is especially advantageous for applications with space limitations, with customizable width and adjustable discharge port height to avoid excessive elevation.

The sieves and screen frames can be equipped with:

- Screen mesh cloth: Typically made from high-quality stainless steel AISI 304 and 316. Cleaning devices, such as bouncing balls, can be added to enhance capacity and prevent clogging, making them ideal for sieving granular and powdered materials.

- Perforated plates: Made from AISI 304, AISI 316 stainless steel, or polyurethane materials, these plates are used for screening larger particles and materials with higher specific gravity.

Thanks to their compact design, these sieves can be fitted with an air ventilation system to cool or dry materials during the separation and conveying process.

VAAPRO’s rectangular sieves can be installed immediately before a vibrating spiral conveyor, classifying powders or granules prior to vertical elevation and transport.

Available in various sizes and fully customizable to meet specific customer needs.

Company

VAAPRO S.r.l.

VAAPRO is a global leader in vibrating sieves and screening solutions, with nearly 70 years of experience. Based in Milan, we serve over 65 industries worldwide, delivering innovative separation equipment. We produce a wide range of vibratory sieves, all 100% Made in Italy and customized according...

Categories

Company

VAAPRO S.r.l.

VAAPRO is a global leader in vibrating sieves and screening solutions, with nearly 70 years of experience. Based in Milan, we serve over 65 industries worldwide, delivering innovative separation equipment. We produce a wide range of vibratory sieves, all 100% Made in Italy and customized according...